Continuous Extrusion Process Principle

Product Description

Principle of continuous extrusion Pinciple of continuous cladding

Top reason to select

1. Superior Performance with Lower Price and Higher Output

2. Over 20 Years Thorough Research and Application

Patented planetary brush and high pressure vortex aluminum cleaning units

Dedicated designed chambers and dies tooling Super-high 100MPa hydraulic system and 250MPa wheel clamp technology

Nominated 8 states level "scientific and technical award"

3. Proved Practical by Over 100 Installations

Skilled technicians, special measure tools to ensure the quality

4. Robust Machinery in Manufacture, Design, Production

Long life for the spare parts

Numerical simulation for the design of the machine, die and chamber

FEM Stress Check for the model of the machinery

EDM and NC guarantee the parts precision

5. Reliable Source of All Electric and Mechanic Components

DC motor, ABB, Mitsubishi electric components

Eurotherm ADC inverter and ADLINK PC

NBZD gearbox and Rextoth hydraulic

6. Universal and Flexible

Capable of continuous extrusion and continuous cladding purpose

Transform to cooper or aluminum production

Harden apparatus to control the hardness of the flat wire

7. Advanced Automation Computer Control System

User friendly touch screen GUI

Present and record all aspect information of the whole process

Adopt Fuzzy logic, neural network and PID loop control technologies

Simple button click and manipulation the whole process

8. Rapid Feedback Support Team

Deliver primary spare parts within 2 days after order

Engineers on-site service within 3 days after customer claim

9. Full Range of Machinery for Customizable Turn-key Project

Advanced Machinery y

Universal SLJB350 capable of continuous extrusion and continuous cladding purpose

Interchangeable TLJ series machinery can adopt both cooper and aluminum as feedstock

Cleaning Patented planetary brush and high pressure vortex aluminum cleaning units

Chambers Dedicated designed chambers and dies for various copper and aluminum products

FEM FEM stress check by I-DEAS for the machinery parts during the CAD process

Simulation Deformation process has been numerical simulated and optimized via the DEFORM simulation software

Manufacture High quality material in the manufacture, special heat treatment for the principal parts and result high reliable machinery

Exactness Manufactures for the important parts are NC and EDM methods

Strength Hardness of the flat wire can be adjusted by the hardener unit

Take-Up Automatic and synchronous take up by speed control and tensile control

High Pressure The super-high hydraulic can reach the high pressure of 100MPa

Production Tooling

Tooling supplied by our company using the computer controlled equipment particularly use in dies, die mandrel sets and die chambers.

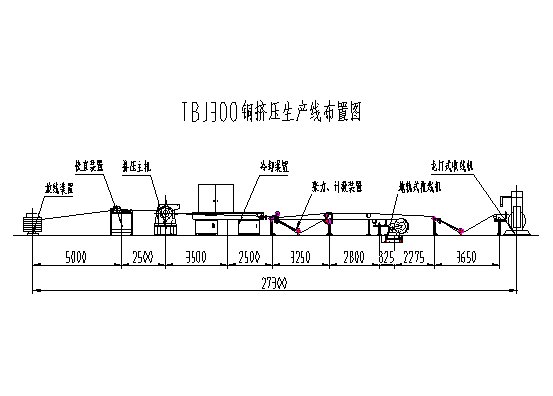

Continuous extrusion, TBJ300 series, adopts advanced technology in the world, continuously feeds the raw material like rod of certain specification into revolving squeeze roll grooved. The rod is to be rubbed and extruded in the holddown groove, generating sufficient temperature by enormous force of friction and extrusion and getting state of recrystallization, then to be extruded and formed in one piece through cavity and the purpose-made die, which could promptly make various copper or aluminum flat wire with high quality.

Product Image